Intermediates and Adaptors for Press Brakes

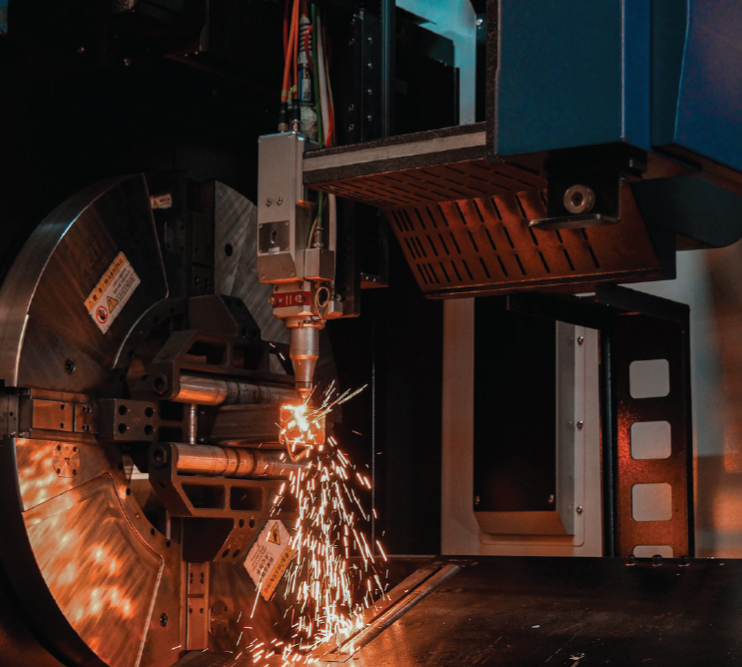

In the world of metalworking, especially in press brake operations, the need for precision and adaptability cannot be overstated. Press brakes are essential machines for bending sheet metal and other materials to precise angles. However, the tooling used in these machines plays a crucial role in ensuring that these processes are carried out smoothly and accurately. Among these critical tooling components are intermediates and adaptors. These parts are integral in enhancing the functionality, flexibility, and performance of press brakes, making them indispensable for a variety of bending applications.

What Are Intermediates and Adaptors?

Intermediates are components placed between

the press brake's ram and bending tools to ensure proper

spacing and alignment for accurate bending. They fine-tune the

setup, helping achieve the desired bend radius, depth, and

angle.

Adaptors, on the other hand, modify the

press brake setup to fit different tooling options, allowing

for quick tool changes without needing new machines or

extensive downtime. They provide flexibility and versatility

for various die shapes, punch configurations, and tool types.

“Intermediates and adaptors are key components in the optimization of press brake operations. They provide versatility, precision, and cost savings for manufacturers looking to get the most out of their press brake machines.”

Types of Intermediates and Adaptors:

1- Standard Intermediates These are typically used to adjust the height of the press brake tooling and improve the clearance between the ram and the dies. They can be easily swapped in and out depending on the thickness of the material being processed.

2- Quick-Change Adaptors Quick-change adaptors are designed for rapid tool changes, reducing the time spent on machine setups. These adaptors are typically used in high-volume operations where tooling must be changed frequently to meet different specifications.

3- Crowning Adaptors These adaptors are designed for machines with crowning systems to ensure uniform bending along the length of the material. Crowning adaptors correct any deflection in the press brake’s bed, ensuring that the bending pressure is evenly distributed.

4- Customized Adaptors In some cases, specific projects may require custom-made adaptors to meet unique tooling and machine configurations. Custom adaptors ensure that your press brake can handle a wider range of tasks, improving overall flexibility.

TR

TR DE

DE